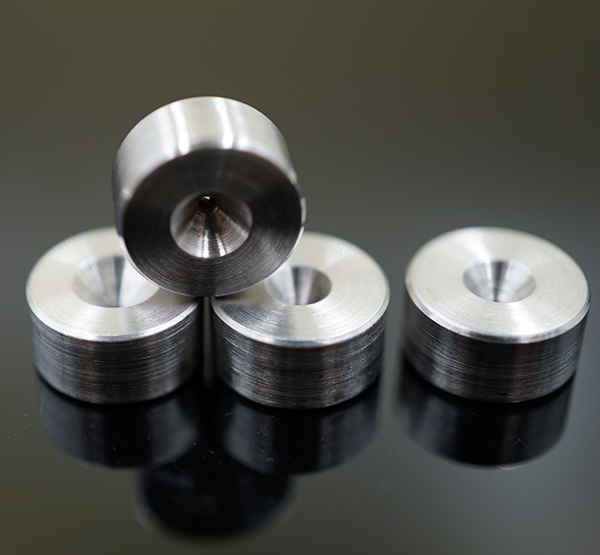

Market Prospects for Diamond Nozzles Replacing Tungsten Carbide Nozzles

This is a highly specialized and pertinent question. The replacement of tungsten carbide nozzles with diamond nozzles is a clear and ongoing trend in the waterjet industry.

In summary, the market prospects for diamond nozzles replacing tungsten carbide nozzles are very extensive. This is an irreversible technological upgrade driven by "cost reduction and efficiency improvement." Although the initial investment is higher, the long-term economic and performance advantages make them the preferred choice for most users seeking efficiency and stability.

I. Core Advantages of Diamond Nozzles vs. Tungsten Carbide Nozzles

To understand the market prospects, one must first understand why the replacement is happening.

Characteristic | Diamond Nozzle | Tungsten Carbide Nozzle |

|---|---|---|

Service Life | Extremely long, typically 500 - 2000+ hours | Relatively short, typically 80 - 120 hours |

Wear Resistance | Extremely high, natural or synthetic diamond is the hardest natural substance | Good, tungsten carbide is very hard, but far less than diamond |

Cutting Precision | Extremely high and stable, orifice size remains nearly constant throughout its life, stream is concentrated | Gradually, the orifice wears and enlarges over time, causing the stream to diverge |

Cut Quality | Consistent, narrower kerf, better verticality, stable quality throughout its life | Gradually deteriorates, kerf widens, taper increases, quality declines later on |

Operating Cost | Lower cost per hour | Higher cost per hour |

Initial Price | High (10-20 times or more expensive than tungsten carbide) | Low |

Core Logic: Users are not buying a "part" but "cutting capability." Diamond nozzles significantly reduce the cost per cut and the frequency of downtime for changes through their ultra-long life and stable performance.

II. Key Market Factors Driving Replacement (Reasons for Bright Prospects)

1. Total Cost of Ownership (TCO) Advantage Becomes Apparent: This is the most fundamental driver. While a diamond nozzle is expensive

Replacing 15 tungsten carbide nozzles plus 15 instances of downtime for labor already approaches or exceeds the cost of one diamond nozzle, which also provides more stable quality and higher efficiency. Decision-makers are shifting focus from "unit price" to "total cost."

2.Manufacturing's Pursuit of Efficiency and Stability: Modern manufacturing has fast pace. Downtime means losses. Frequent tungsten carbide nozzle changes require stopping, disrupting production. Diamond nozzles reduce change frequency from "several times a week" to "once a month or even per quarter," greatly improving equipment utilization and production continuity. This is crucial for automated lines and unmanned workshops.

3.Increasing Waterjet System Pressure: Newer waterjet machines operate at higher pressures (from 380MPa to 620MPa+). Higher pressure means faster water/abrasive flow and more severe nozzle wear. Tungsten carbide nozzle life shortens further under high pressure,放大 (magnifying) the wear resistance advantage of diamond nozzles and strengthening the replacement demand.

4. Gradual Decline in Diamond Manufacturing Costs: As technologies like CVD (Chemical Vapor Deposition) mature and scale, the cost of high-quality diamond materials is slowly decreasing, making diamond nozzles more affordable and accelerating market penetration.

III. Market Challenges and Limitations

Despite bright prospects, the replacement process is not overnight and faces challenges:

1.High Initial Investment Barrier: For small workshops or budget-limited users, the upfront cost of a diamond nozzle remains significant, and they may opt for price-sensitive tungsten carbide nozzles.

2.Loss or Damage Risk: Diamond nozzles are hard but brittle. Accidental impact (e.g., collision with a workpiece) can cause cracking, leading to greater loss. Tungsten carbide nozzles are more "robust," with lower damage costs.

Contact: Jennifer

Phone: 0086-13650067801

Tel: 0086-769-85331667

Email: sales@ch-microhole.com

Add: No.38 XinGang road , Changan town, Dongguan, Guangdong, China

We chat